The rate pendulum has been in the corner of motor carriers in 2018 and will likely stay put through 2019.

The DAT North American Freight Index, a monthly measure of demand for spot market freight, shows that rates peaked in June at 18 percent above the same time last year, and then dipped slightly in July due to seasonality.

The market may be ripe to expand fleet capacity but driver shortages and other constraints are making it necessary to get more from available resources.

Trailer management technology is one lever that companies are pulling to add more capacity without buying more equipment and hiring more drivers.

Making status count

Tiger Cool Express, founded in 2013, buys container drayage from carriers as a freight broker and contracts with railroads for intermodal shipping.

The Overland Park, Kan.-based company started out with 200 refrigerated containers and today owns 750 with plans to reach 2,500 in the next three years. It has been using a fleet management system from Coretex to have near real-time status updates to plan and execute on-time pickups and deliveries.

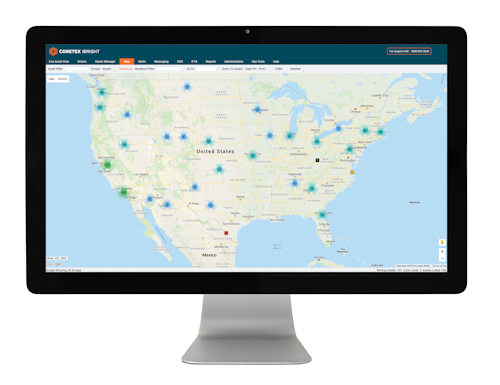

It uses the system, IBRIGHT, to identify the status of containers at pickup locations. The technology shows if they are backed up to docks, if their doors are open or closed, and if their refrigeration units are on or off. With this and other information, users can quickly determine which containers are loaded and available for pickup, says Ted Prince, chief operating officer.

With the IBRIGHT web portal from Coretex, Tiger Cool’s office staff can set temperatures remotely and turn container reefer units on and off.

Using the IBRIGHT web portal, Tiger Cool’s office staff can also set temperatures remotely and turn container reefer units on or off, he says. The system is integrated with Tiger’s transportation management software (TMS) to automatically update container locations and other status details every 15 minutes.

Through the TMS integration, users are notified of any shipments that have exceptions in transit such as if a reefer unit is running low on fuel or not performing correctly, he says.

With accurate status information the company can set realistic delivery appointments to keep assets moving. Many of its customer facilities are “packed,” he says, and “if you miss a delivery appointment the container may be sitting there with the reefer running for a day or two before it is unloaded.”

Being on-time to rail ramps is also essential to avoid downtime. Railroads have cutoff times and the tracking information helps to ensure loaded containers arrive to the ramps on schedule.

Tracking arrivals at the destination rail ramps is also critical. A railroad may notify Tiger Cool Express that a container unit will be available for pickup at midnight, for example. The IBRIGHT system may show that at midnight the unit is still a quarter mile away from the unloading spot, however.

In order to determine when containers are actually available for pickup to set realistic delivery appointments, “we are very carefully watching how it is unloaded,” he says. “Our job as an intermodal provider is to make sure a great number of little things happen on time and correctly.”

Predicting trailer capacity

When making deliveries, drivers often lose productive time unloading or searching for empty trailers to take to their next load appointments. If no empty trailers are available on site, office personnel may begin cold calling customers in the area to locate empty trailers.

U.S. Xpress equips its trailer fleet with a tracking system from SkyBitz with cargo sensors. One of the nation’s largest truckload carriers, the Chattanooga, Tenn.-based company uses the information it receives to predict when trailers will be unloaded and ready for pickup, says Aaron Woods, the company’s manager of trailer management.

U.S. Xpress equips its trailer fleet with a tracking system from SkyBitz. Cargo sensors detect when trailers are empty and ready for pickup.

The SkyBitz system is integrated with U.S. Xpress’ custom transportation management system and with a mapping software tool from ESRI. With the ESRI software, Wood sets up geofences for tracking arrivals, departures, turnaround times and trailer inventories by customer location and by geographical planning regions.

“The big thing that bites us and any carrier is when we have loaded trailers going into markets where we do not have loaded freight out,” he says.

The company is managing trailer counts in each planning region to maintain the balance of trailer capacity across its freight network. At times, U.S. Xpress will use secondary carriers and railroads to reposition its trailers in its network, he says.

In the three years U.S. Xpress has been using the SkyBitz trailer tracking system its trailer count has gone from 17,000 to approximately 14,000 by increasing efficiency and the capacity that is available in its network, Wood says.

With the SkyBitz system, U.S. Xpress can also identify trailers at locations that have not moved for an extended period. These events signal possible mechanical defects on trailers that are causing drivers to not hook up.

U.S. Xpress is also increasing trailer capacity by monitoring their use by third-party carriers and shippers that have interchange agreements.

“We know when one of our trailers starts moving,” Wood says. Its system tracks where trailers are picked up, dropped, and how many miles they moved so the company can efficiently bill carriers for the authorized or non-authorized use of its trailers.

Original Source: https://www.ccjdigital.com/fleets-use-trailer-technology-to-move-freight/