In this special report, we celebrate the amazing people and companies in our industry who have stepped up with hard work, impressive innovations, and extraordinary measures to help meet Covid-19–related supply chain challenges.

Whoever would have thought that the turn of a new decade would bring such a cataclysmic event to our world? Our economy was humming along. Times were good, and business was booming. Then along comes a pestilence in the form of a microscopic virus that has shaken our world to its core.

Tens of thousands of Americans have died. Hundreds of thousands have become ill. Millions have lost their jobs. And tens of millions have been isolated and socially distanced from friends and loved ones. History will look back on the Covid-19 pandemic as a turning point in our lives.

And while all of this has been going on, manufacturers continue to produce goods, warehouses process orders, trucks roll and deliver, and supply chains continue to function.

It has not been without a hitch, but supply chain has certainly been among the few bright spots during the pandemic. Finally, every American is aware of what supply chain professionals do each and every day without fanfare. Warehouse workers and drivers continue to show up for work, risking their health and their emotional well-being to keep freight moving.

In the following stories, we salute some of the many individuals and companies who have used their talents and resources to bring healing and hope, deliver comfort, and save lives during the Covid-19 crisis. We thank these unsung heroes who have quietly gone about their work to make sure the rest of us have what we need to make life appear almost normal.

Logistics firms dig deeper into technology to manage Covid-19 volatility

Stepping up their use of technology is one of the many ways logistics firms are meeting volatile business conditions brought on by the Covid-19 pandemic. Fort Wayne, Indiana-based Circle Logistics and White Plains, New York-based Capital Logistics are two examples of companies digging deeper into visibility tools to help monitor and manage freight shipments, especially for critical food and medical supply chains.

Both companies said this spring they were using Descartes Systems Group’s MacroPoint real-time freight visibility solution to track critical loads for customers such as the Federal Emergency Management Agency (FEMA) and major grocery brands. Circle Logistics said it shifted its entire transportation network to manage a 700% increase in volume from customers moving critical freight, including personal protective equipment (PPE), respirators, cots for FEMA, and grocery loads. Company leaders said the platform allows it to better track the movement of goods under volatile conditions.

At Capital Logistics, leaders are also integrating Descartes’ Aljex cloud-based transportation management system (TMS) to manage volatility. Designed for freight brokers, the system automates planning, freight tendering, and dispatching as well as back-office functions including accounting, invoicing, and reporting. The integration with MacroPoint provides real-time freight visibility to automatically track loads, “greatly reducing the manual efforts for track-and-trace teams,” according to Descartes.

“As our customers focus on keeping food supply chains functioning, having real-time visibility into the status of critical freight has increased our ability to keep pace with the unpredictable demand grocery stores are experiencing,” Greg Ackner, vice president at Capital Logistics, said in late April. “In one case, we went from moving two to three truckloads of milk per week to distribution centers serving multiple states to 50 to 60 truckloads per week.”

Combilift develops ventilator device

Forklift vendor Combilift is stepping up to address the shortage of medical equipment for treating Covid-19 patients by developing a splitter device that turns one ventilator into multiple ventilation stations.

Monaghan, Ireland-based Combilift used its resources in engineering and software design to pivot from the material handling sector to create the “Combi-Ventilate,” saying the unit will address the requirements of medical professionals in the Covid-19 emergency.

The Combi-Ventilate uses standard pipes and fittings for easy assembly, offers individual patient filters that prevent cross contamination, and supports dedicated computer screens for each patient’s vital information. The device is designed as an attachment that can be added to any brand of ventilator, installed easily into a hospital’s intensive care unit (ICU), and purchased for a fraction of the cost of a standard ventilator, the firm said.

Food industry groups partner to keep supply lines open

The International Foodservice Distributors Association (IFDA) and FMI-Food Industry Association are partnering to help keep store shelves stocked amid the coronavirus pandemic. In March, the groups announced a partnership that aims to match food-service distribution companies that have excess product, warehouse space, and transportation capacity with food retailers and wholesalers in need of assistance, the associations said.

The partnership addresses the issue of excess product and capacity caused by the closing of restaurants, schools, and other businesses with retailers and wholesalers seeking to replenish store shelves more quickly. IFDA and FMI are gathering information from their members and matching capacity to need geographically, essentially functioning as a clearinghouse for contact information, according to IFDA spokeswoman Meghan Cieslak. She emphasized that the program aims to help fill demand for products but will also help fill demand for trucks, drivers, warehouse staff, warehouse storage, and similar needs.

MH Equipment funds food banks, employee volunteer work

The Illinois-based material handling equipment dealer MH Equipment has used its corporate charity program to support several initiatives during the economic shutdowns and shortages caused by the Covid-19 pandemic.

First, the firm launched a campaign to address food shortages faced by community food banks and pantries during the coronavirus emergency. The company’s “Purpose Unites” program allows employees to automatically deduct part of their paychecks to support local food banks. Along with donations from the company’s “His First Foundation” charitable program, the effort raised nearly $187,000 across 33 office locations in just four days.

Second, the company’s charity arm paid many of MH Equipment’s own employees to perform volunteer community service, using spare time they had available due to a drop in demand during the recession. MH Equipment compensated them for more than 4,000 hours of volunteer community service time across several Midwest states throughout the month of April. Those tasks included helping food banks with loading/unloading trucks, meal delivery, and packaging; making masks; mowing yards for the elderly and for nonprofit organizations; and using their technical skills to assist with light mechanical work on fire engines at volunteer fire departments.

DDC FPO and TEAR partner to donate PPE kits to truckers

Truck drivers moving in and out of hot zones to perform essential work are receiving personal protective equipment (PPE) thanks to a collaboration between DDC FPO, a back-office partner for the transportation industry, and Truckers Emergency Assistance Responders (TEAR), a 501c3 nonprofit organization founded with the mission to help truck drivers in distress.

TEAR has built and deployed a network of corporate sponsors and volunteers to source, assemble, and distribute PPE kits to truck drivers on the front lines. Delivered at truck stops and rest areas, each PPE kit includes masks, hand sanitizer, gloves, antiseptic wipes, and snacks. “The drivers are so appreciative,” TEAR leader Desiree Wood said. “They spend all day by themselves and aren’t used to receiving anything for free, let alone being recognized. They are thrilled to receive the kits.”

Trimble offers free app to help truckers locate amenities

Supply chain technology provider Trimble Inc. has launched a free web app that displays truck-stop status and amenity information, allowing truck drivers to find essential break locations, showers, and restaurants.

The information comes as many break locations have closed completely or have shuttered certain amenities during the coronavirus crisis. Currently available on desktop or mobile devices in North America only, the “Covid-19 Safe Haven Web App” is intended to help the transportation community find out which locations are closed and which conveniences are open. Drivers can also use the platform to find Walmart locations with overnight parking, view live traffic and weather reports, and help their peers by reporting location closings.

Amazon.com teams up with Boston Scientific to deliver face shields

E-commerce retailer Amazon.com Inc. has teamed up with medical device manufacturer Boston Scientific to deliver donated face shields to health-care facilities around the U.S. fighting the Covid-19 pandemic.

Health-care volunteer coalition GetUsPPE organized the effort, under which Boston Scientific mobilized employees at a dozen sites to produce and donate the personal protective equipment (PPE), while Amazon offered logistics support. Amazon provided space on its trailers to deliver the shields from Boston Scientific to local delivery stations, where Amazon associates have worked with delivery service partners in Chicago, Detroit, and the Washington, D.C./Baltimore metro areas to deliver the face shields to hospitals and clinics.

Goodwill makes masks for Ryder essential staff

Job training nonprofit group Goodwill of South Florida has converted a portion of its sewing operations to manufacture 20,000 masks for employees at transportation and logistics company Ryder System Inc. The initiative extends a long relationship between the two organizations, since company founder James Ryder was also one of three founders of Goodwill some 60 years ago, David Landsberg, CEO of Goodwill of South Florida, said in a release.

The masks are being used to protect Ryder’s essential employees as they support the flow of goods and services needed in the fight against Covid-19. Each mask is made with camouflage material on the outside, a softer fabric on the inside, and elastic ear loops.

Kia Motors manufactures face shields on assembly lines

Automaker Kia Motors America is donating personal protective equipment (PPE) to hospitals and medical facilities during the Covid-19 crisis. The face shields are assembled at its Kia Motors Manufacturing Georgia plant in West Point, Georgia, and the brand plans on donating a total of 300,000 face shields nationwide.

A group of company volunteers called “Telluriders” recently delivered face shields to Morristown Medical Center/Atlantic Health in Morristown, New Jersey. The deliveries were part of Kia’s “Accelerate the Good” initiative, which includes ongoing face shield donations to medical facilities in New Jersey, Southern California, and Georgia.

Sierra Nevada uses beer lab to make Covid-19 test kits

Beer maker Sierra Nevada Brewing has donated some of its food laboratory resources in Chico, California, to making a critical component used in tests for detecting Covid-19 infections.

Sierra Nevada is using its quality assurance lab—usually dedicated to testing beer for unwanted bacteria and wild yeast—for creating the “viral transport medium” that is in short supply for enabling coronavirus tests. The medium is used to protect the swab that doctors insert into patients’ nostrils while it is transferred to a medical lab. In this case, the beer maker has already delivered 1,000 vials of the liquid to California’s Enloe Medical Center and is planning to make up to 10,000 more.

Atlantic Logistics supports Florida truckers with hand sanitizer, masks

Employees at Jacksonville, Florida-based third-party logistics service provider (3PL) Atlantic Logistics have started a bulk hand sanitizer rebottling program that will serve local truck drivers. In April, employees partnered with TravelCenters and TA-Petro to set up personal distribution of hand sanitizer and masks to drivers at their truck stop at I-10 and U.S. Highway 301 in Jacksonville.

“Most Americans want to give back and say ‘Thank you’ to the truckers that keep the shelves stocked and the country moving,” Rob Hooper, Atlantic Logistics’ CEO, said in a statement. “I’m so proud of the initiative our employees took to help make these folks’ lives a little safer and simpler.”

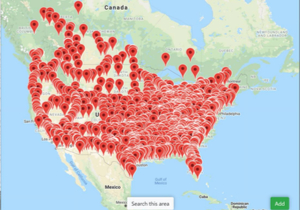

Volunteers build mobile app to link truckers with food, fuel, Wi-Fi

Volunteers from the North American technology community have banded together to build a mobile app that helps truck drivers find essential services near their current locations, so they can continue operating safely during the Covid-19 pandemic.

Known as “Truckers Welcome,” the site serves as a “social application” that lets businesses add and share information about the services they are still able to provide to drivers—such as drive-through meals, washrooms, Wi-Fi, and fuel. With over 1,600 locations registered across the U.S. and Canada since it launched, the site addresses some of the significant challenges truck drivers face while on the road keeping goods and supplies flowing to grocery stores, hospitals, and communities, its creators say.

Logistics Plus donates 3PL services to deliver 50,000 surgical masks

Third-party logistics service provider (3PL) Logistics Plus Inc. provided free customs clearance and delivery services to transport a load of 50,000 surgical masks for the city of Erie, Pennsylvania.

The masks were originally donated by Erie’s sister city, Zibo, China, and airfreighted to Chicago. Erie-based Logistics Plus then facilitated the customs clearance and paperwork, took possession of the shipment, and arranged complimentary transportation of the goods from Chicago to Erie.

“Together we are ‘Erie Strong,’” Jim Berlin, founder and CEO of Logistics Plus, said in a release. “Helping [Erie] Mayor [Joe] Schember and the city get these masks from Chicago to Erie and in the hands of our front-line government workers was an easy decision. It feels good to donate and to do something for those in need.”

Raymond Corp. produces 2,000 face shields for health-care workers

The Raymond Corp. put its weight into the Covid-19 fight to help local health-care workers and first responders. The New York-based maker of forklifts and other material handling equipment and solutions used its engineering might to 3D print and assemble face shields at its Greene, New York, facility. Company President and CEO Mike Field said in April that Raymond would produce 2,000 face shields to be distributed to local hospitals and first responders.

“Like everyone, we at Raymond have heard the appeals for protective equipment from our local health-care workers battling the Covid-19 pandemic,” Field said in a release. “Raymond has the ability and desire to utilize our vast production capabilities to support those crucial employees. … We will continue to monitor the evolving situation to determine how best we can support our local health-care heroes.”

Tech firm Resilinc launches health-care industry exchange for PPE, medical supplies

Supply chain technology and risk management firm Resilinc responded early to increased demand for critical health-care supplies by launching the The Exchange at Resilinc, an online clearinghouse designed to match available inventory with hospitals that need items, including personal protective equipment, to fight the Covid-19 pandemic. The company announced the initiative March 25, and the exchange was up and running by mid-April.

Resilinc partnered with representatives from the health-care and logistics sectors to create the exchange, which will allow group purchasing organizations (GPOs), distributors, and hospitals to connect and exchange inventory and to access donated inventory from manufacturers and other organizations. The program is designed to digitize and broaden a system that is largely done informally and manually between trading partners. The exchange will be free for all U.S. hospitals through September, according to Resilinc Founder and CEO Bindiya Vakil.

ATA enhances #thankatrucker campaign with additional front-line initiative

The American Trucking Associations (ATA) joined with corporate partners to further its #thankatrucker campaign, launching its “Providing for the Frontlines” initiative in May.

Insurance provider OneBeacon, U.S. Bank, Michelin, and Hydro-Chem Systems are partnering with ATA to provide hand sanitizer nationwide as well as meals for professional truck drivers on the road, the groups said.

“This new initiative aims to celebrate unsung heroes in the trucking industry who continue to bravely deliver America’s goods throughout the ongoing coronavirus pandemic, as well as provide relief to the hard-working men and women behind the wheel,” Arlington, Virginia-based ATA said in a statement.

The initiative will include a photo contest in which drivers can submit a fun photo of themselves and their rig. Once submitted, they will be entered into a drawing to win a $25 electronic gift card for a meal of the driver’s choice while on the road. Multiple winners will be selected daily. Truckers can enter and anyone can view the daily winners at www.trucking.org/thankatrucker.

Providing for the Frontlines builds on ATA’s efforts to support truckers nationwide. Also in May, the association teamed up with Protective Insurance and ABF Freight to supply 550 gallons of hand sanitizer to eight states across the country. By mid-month, thousands of drivers had been able to refill their personal supply at no cost to them, ATA said.

Brain Corp. donates $1.6 million of robotic floor-cleaning services

Logistics robot technology provider Brain Corp. is donating $1.6 million worth of autonomous floor-cleaning robots and services to essential businesses during the Covid-19 pandemic.

Autonomous mobile robots (AMRs) are playing a vital role in helping support essential businesses and their workers on the front lines of the health crisis, since retailers, airports, and hospitals are required to clean more frequently and deliver more cleaning coverage than usual. Autonomous floor scrubbers powered by Brain Corp.’s BrainOS software are providing more than 8,000 hours of daily work—equal to a quarter-million hours throughout the month of May—that otherwise would have to be done by an essential worker, the company said.

Gebrüder Weiss USA, Delta Group Logistics, Seko Logistics donate PPE

Transport and logistics firms Gebrüder Weiss and Delta Group Logistics teamed up to deliver thousands of pieces of personal protective equipment (PPE) to health and safety workers in the Chicago area as they continued to fight the Covid-19 pandemic in May.

The companies purchased and distributed 8,000 face masks and 1,000 face shields to various organizations and companies in Chicago and the surrounding suburbs. A majority of the face shields donated went directly to Springfield, Illinois, to help stock the Centers for Medicare & Medicaid Services’ state surplus warehouse so that shields are ready when they are needed, the companies said.

The companies planned to continue donating PPE throughout the month.

Separately, Illinois-based Seko Logistics has stepped up its own PPE efforts with donations for front-line workers and by providing additional equipment for its own essential workforce, the company said.

As of mid-May, Seko Logistics had distributed more than 28,000 face masks and 138,000 gloves to its front-line teams in North America along with additional PPE kits for its MedTec drivers, which support medical deliveries nationwide. That comes on top of a pledge to donate $200,000 for the purchase of PPE for health-care workers treating Covid-19 patients around the country.

Axalta shifts manufacturing line in Mexico to produce hand sanitizer

Liquid and powder coatings supplier Axalta has shifted the manufacturing capabilities of its facility in Tlalnepantla, Mexico, to produce more than 1,000 liters (264 gallons) of hand sanitizer, which is being donated to local health-care facilities, first responders, and other essential businesses.

These efforts complement Axalta’s global support of coronavirus relief efforts, which include sending personal protective equipment (PPE) to hospitals in the U.S., France, Belgium, and Germany, and providing more than 5,000 seat covers to medical professionals, who can use the seat covers in their own cars to reduce the risk of transmitting the coronavirus when they are visiting those infected with the virus.

Lockheed Martin donates air-cargo capacity

Aerospace and defense contractor Lockheed Martin Corp. has donated cargo capacity on its corporate aircraft as an in-kind donation to support the federal government’s Covid-19 response for medical transplants, helping ensure that the life-saving products from European donors reach American patients on time.

The flights help ensure the timely delivery of bone marrow and blood stem cells for transplant, a need that arose when the National Marrow Donor Program (NMDP)/Be The Match ran out of available European Union couriers to deliver life-saving cells to U.S. patients, since tens of thousands of commercial flights had been canceled during the pandemic. Lockheed Martin will be providing weekly air transport based on government medical need—flying government medical teams to the most critical, high-priority locations around the country and/or flying to support bone-marrow transport to help with the government’s coronavirus response.

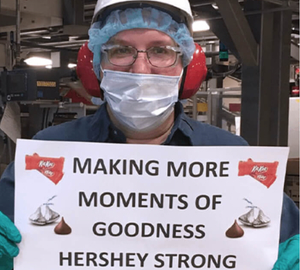

Hershey acquires assembly line for face masks

Chocolate maker The Hershey Co. has committed $1 million to acquire, install, and staff a new manufacturing line dedicated to the production of face masks during the Covid-19 emergency.

Leveraging its internal engineering capabilities and its relationships with equipment manufacturer JR Automation and General Motors, which is making similar masks, the company is moving quickly to address the nationwide shortage of protective equipment. When it becomes operational, the Hershey, Pennsylvania-based line will be capable of producing up to 45,000 masks per day, the company said in mid-May.

DHL, Royal Bay, LocatorX launch medical/PPE initiatives

Transportation and logistics services provider DHL Global Forwarding, packaging and design venture Royal Bay, and tracking technology firm LocatorX have stepped up to provide personal protective equipment (PPE) and other services to front-line workers.

DHL Global Forwarding is partnering with customers in the health-care industry to ship more than 100 tons per week of medical supplies, equipment parts, pharmaceuticals, and protective clothing for hospitals, health-care workers, and patients throughout the United States and is also offering special charters to and from China to ease the capacity crunch for customers, officials said in May.

Royal Bay, a joint venture between packaging and design companies Bay Cities and The Royal Group, is assembling and packaging 2 million face shields for essential workers. The shields will be distributed to medical suppliers and distributors, who will send them to medical facilities and hospitals nationwide. At capacity, Royal Bay will assemble and package 500,000 units per week, the companies said.

Atlanta-based tracking technology firm LocatorX has launched a National Medical Device Registry allowing hospitals to log their life-saving equipment at no cost during the Covid-19 crisis. The registry will also help hospitals quickly and easily identify the status of venilators available for loan, the company said.

Original Source: https://www.dcvelocity.com/articles/46391-heroes-of-the-supply-chain